For most artifical accelerated tests in laboratory, getting a consistent testing results with outdoor is the most important purpose. Prior to cyclic corrosion testing, conventional salt spray (a continuous salt spray at 35˚C), was the most popular way to simulate corrosion in a lab. Because conventional salt spray methods failed to simulate the natural wet/dry cycles of the outdoors, test results frequently provided poor correlation to outdoors.

In a typical cyclic corrosion cabinets, all specimens are exposed to a series of different environments in a repetitive cycle that simulates the outdoors . Simple cycles, such as Prohesion, may consist of cycling between salt fog and dry conditions. More sophisticated automotive methods may ask for multi-step cycles that incorporate humidity, dry air or condensation, along with salt spray and dry-off.

Within one chamber,users can cycle easily through a series of the most significant corrosion environments. Even extremely complex test cycles can easily be programmed with the controller. Biuged CCT Cabinets can perform salt spray, Prohesion, and 100% humidity for most cyclic automotive tests.

The Cyclic Corrosion Test Cabinets developed and produced by Biuged sets and controls various parameters through the touch screen, and combines multiple tests such as salt spray corrosion, humidity (high temperature and high humidity, low temperature and low humidity), air drying(hot drying and air drying)to simulate a variety of cyclic corrosion tests. Of course, special cyclic corrosion test can also be simulated through the combination of other accessories. The instrument can also conduct neutral salt spray test(NSS), acetic acid salt spray test(AASS), copper accelerated acetic acid salt spray test(CASS), water spray test, damp heat test, drying test and standard atmospheric environment test separately.

Standards

ISO 4611《Plastics—Determination of the effects of exposure to damp heat, water spray and salt mist》

ISO 7253《Paints and varnishes -- Determination of resistance to neutral salt spray (fog) 》

ISO 9227《Corrosion tests in artificial atmospheres -- Salt spray tests》

ISO 11493《Corrosion of metals and alloys - Accelerated testing involving cyclic exposure to salt mist, "dry" and "wet" conditions》

ISO DIN EN 16151《Corrosion of Metals and Alloys - Accelerated Cyclic Tests With Exposure to Acidified Salt Spray, ''dry'' and ''wet'' Conditions》

ISO 16701《Corrosion of metals and alloys -- Corrosion in artificial atmosphere -- Accelerated corrosion test involving exposure under controlled conditions of humidity cycling and intermittent spraying of a salt solution》

ASTM B 117《Standard Practice for Operating Salt Spray (Fog) Apparatus》

ASTM B368《Standard Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test) 》

ASTM B 380《Standard Test Method for Corrosion Testing of Decorative Electrodeposited Coatings by the Corrodkote Procedure》

ASTM G85 - 11《Standard Practice for Modified Salt Spray (Fog) Testing》

ASTM D 1735《Standard Practice for Testing Water Resistance of Coatings Using Water Fog Apparatus》

DIN 50021《Salt Spray Testing》

1. Cabinet Material

◆ Cabinet inner layer is made of 8mm thickness CPVC, the max.enduring temperature is 100℃;

◆ Cabinet outer layer is made of imported 6mm thickness PVC the max.enduring temperature is 85℃

◆ Inner box for controlling dry and humidity is made up of SUS 304# stainless steel, outer box is made of PVC. All insulation material is made of polyurethane (PU) epispastic plastic

◆ Sealing cover of working room is made of 8mm CPVC, with strengthening treatment. V shape , the top ange is 100º, prevent condensate water during the test from dropping to specimen surface and affect testing results. Moreover ,there is a transparent observing window made of tempered glass (400mm*400mm)

◆ Humidifying Tower:made of SUS304# stainless steel, endurable high pressure and good thermal insulation effect.

◆ Salt Solution Reservior:made of CPVC, 25L capacaity

2. Design Features

◆ Working: Sperate dry-wet test from salt spray test. When cabinet is working under salt spray testing, dry-wet controlling system would be closed automatically, avoid effectively salt fog to damage refregeration system. When cabinet runs dry or wet test, system would switch to dry-wet controlling box by ventilation door, and salt spray testing would be stopped automatically. Intelligent TS time signals cycle the cabinet run dry, wet and spray salt test automatically.

◆ Overall Design:Left-middle-right arrangement for controlling box and working room:salt solution reservoir, water supply reservoir for humidifying, humidifying tower are on the left, working room in the middle and dry, wet controlling box on the right. Electric system is separated from water system, avoid water to enter electric control box to damage accessories.

◆ Panel Supports: A plane indexing rack is designed on the top of working room. Panel racks are divided into three layers: the upper layer is used to put round rod which is made of corrosion-resistant material, the middle layer is used to put V shape glass fiber rack. Through V shape rack and round rod position, the exposuring angle of specimen panels can be adjusted to three different as 15 º、30 º、45 º. The last layer is used to put big sample, a punched CPVC board is designed at the bottom of working room , this board is above the heating layer of cabinet (height from bottom is approx..250mm).with distributed uniformly holes design, it can avoid gathering too much solution, also be in favor of air-circulation in working room.

3. Spray Fog System

◆ Spray Fog Principle:Use Bernouilli’s principle to absorb salt solution then atomize it, no any salt would crystallize at the spray nozzle and ensure a uniform fog distribution in whole the working room and continuous testing.

Air Compressor→Oil-water Separator(first)→Air Storage Tank→Relief Valve→Total Solenoid Valve→Oil-water Separator(second)→Saturator→Pressure Regulating Valve→Solenoid Valve for spraying→Spray Nozzle

◆ Sprya Apparatus:There is one or two atomizer towers in the middle of working room, ensure a uniform fog distribution in the room. At the bottom on atomizer tower, a salt solution supplying container is installed, in this container, there is a corrosion-resistant float for controlling water level which is used to control water level in the container automatically. Spray nozzle is installed above the container within 100mm height to ensure siphon range for spraying. On the top of spray nozzle, there are some extended CPVC pipes which ensure what the tested samples get are all fog ions, avoid condensate water because of imcomplete atomization during the test from dropping to specimen surface and affect testing results.There is a subulate block whose height can be adjusted on the top of pipe, by adjusting the taper height, spraying amount can be adjusted to the standard requirements(1~2ml/80cm2·h)

◆ Fog Collectors:Tow fog collectors (tapered funnels whose diameter are 100mm)are used to monitor spray fog amount, one is near the atomizer tower and the other is far from. At the bottom of the funnel, there is a silicone pipe which connect with graduated cylinder installed outside. Operator can check the amount of collecting liquid in the graduated cylinders to judge if the spray fog amount is enough or not.

◆ Spray Nozzle:Made of special glass, can control fog amount and spraying angle

◆ Spray Fog or Drain-away Fog:Spray fog can be done by manual or setting a program. Draining-away fog also can be run by manual or setting a program(feed fresh compressed air to working room then drain away the fog of the working room quickly)

4. Main Components

◆ Sealing System:Cabinet body is seald by high-temperature resistant and corrosion resistant silicone rubber, ensure corrosive gas don’t leak. A air cylinder is designed to control cabinet’s cover lifting up and down(by manual or automatically, and speed can be adjusted by air pressure.),simple to operate. Moreover, specially designed air-door device can switch between salt spray test with temperature-humidity test, avoid effectively corrosive gas to enter the dry-wet controlling box and damage some components.

◆ Air Circulation System: There is a air room and a stainless steel wind turbine, through ventilation door, air is blowed out thourgh the air duct. Thus the air which have been adjusted to required temperature and humidity would be distributed to working room, then attain the goal which can ensure to get a stable working room with uniform temperature and humidity

◆ Heating System:Control heating amount by PID , then arrive a temperature balance. Humidifying and warming room adopts a Inconel heater, a wind turbine to supply air for a strong circulation. For working room, heating tube is made of titanium alloy heating tubes, heat air directly. For humidifying tower, uses a Armoured SUS316# electirc heating tube to heat water. Pressured air enter the hot water, then overflow by the bubbles, thus get constant temperature and pure air for sprying

◆ Humidifying and dehumidifying system:adopt water steam to humidify and run the compressor to dehumidify. P.I.D control humidifying amount to get the required humidity.

◆ Humidifying Tower:Is made of SUS304# stainless steel.In order to ensure the pressured air for spraying is pure and with constant temperature, there is a specially designed heating apparatus for filtering air. Moreover, there are controlling water level apparatus, heating apparatus and controlling temperature system in this humidifying tower.At the bottom of tower, there are many small holes for overflowing pressured air.

The outside of humidifying tower connect with oil-water separator and pressure regulating valve of the air source. Pressure air to required value firstly then let air enter heating system, and water of humidifying tower through the small holes at the bottom of tower, and overflow by bubbles, then arrive the top of tower and supply the spray nozzle for spraying.

There are two water level sensors for supplying water automatically, one is near the bottom, the other is near the top, ensure humidifying tower’s water level keep stably a required height , then ensure not only to get a pure saturated vapor, but also keep pressured air temperature be within required range for a long time. At the same time, there are also water level monitoring and limitation value alarm functions

5. Operation System

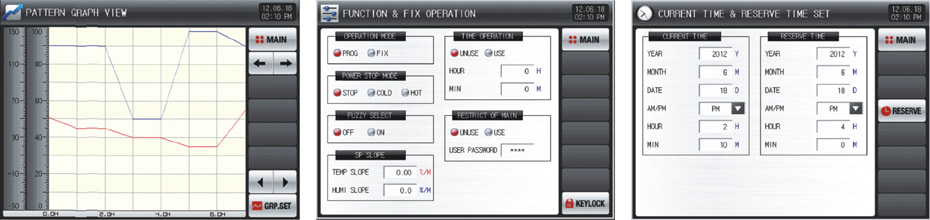

◆ Imported programmable TEMI 2500 controller (Touch screen):5.7 inches, 800×480 lattice, TFT colorized LCD screen, show current working room temperature value and set temperature value, current RH value and set RH value, temperature current value and set value of humidify tower, set time and running time of test. At the same time, all shown temperature, RH and salt fog change datas can be recorded and downloaded in real-time

◆ Programmable:spray time and interval time can be set freely, max.continuous spraying time is 999.9 hours, max. spraying time for discontinuous spray is 99 hours and 59 minutes,max interval time(no spray)is 99 hours and 59 minutes; Can edit 120 programs, each program consists of 1~99 segments. Memory capacity is 1,200 segments and can execute command repeatedly (each command can be executed for 999 times).Different program time can be combined to run, segment time can be set from 1minute to 999 hours.

◆ Communication Function:RS-485/RS-232 interface, with local and telecommunication function. System come with a monitoring softwar(need one COM port of PC), and can connect up to 16 computers. Operator can transfer freely all datas collected by monitoring software to EXCEL format

◆ SD Card:Come with a SD memory card, a software CD for PC. User can edit a program by software specialized for PC and store it in the SD card, then call out this program and store it in the controller. Of course, user also can copy the program in the controller to SD card, then store it in the PC to manage and analyze.

User also copy the testing data graph stored in the controller to SD card, then show or print it by PC software(the printed data has a remark“no revise”), or transfer it to Access data file by Microsoft office.

Test data graph recorded by controller is : 2 routes temperature (set temperature and real-time temperature);2 routes relative humidity(set RH and real-time RH)

6. Cooling System

◆ Cooling Methods: Use a set compressor as cooling system, including a low-temperature cooling compressor imported from Europe, fined tube radiator, air-cooled scale-type condensation evaporator and throttle device (thermal expansion valve/capillary), and use environment-friendly refrigerant R404a/R23 as this cooling medium of this system.

◆ Features:

A. All pipelines of system have passed by 22kg pressure leakage checking

B. Heating system and cooling system is separated completely.

C. With our company professional technology, design a special protection system to avoid high temperature and high pressure to start compressor

D. All programs run cooling sysem are controlled by micro-computer completely.

E. At the bottom of compressor, there is a drain pan which is used to collect condensation water generated from frosting

F. Compressor comes with PTC temperature sensor, can protect itself once the temperature is over.

G. With high or low pressure protection device, it can monitor the pressure of refrigerant when the chamber is working. Once the refrigerant pressure is higher than limiting pressure or lower than the lowest pressure set by system, it can alarm and power off till troubleshoot all problems.

H. The whole cooling system is imported from imported brand, reliable quality and ensure a stable system.

7. Safety Devices

◆ Cooling System:For compressor, over-heat, over-load, over-pressure and over-temperature protectiuon

◆ Chamber:Over limiting temperature protector, balance pressure automatically protector,prevent water at the bottom protector

◆ Humidifying System:Dry heating protector, water shortage protector for humidifying tube,

◆ Heating System:Over limiting temperature protectorand short circuit protector for heating tube

◆ Power:Over-load protector, short circuit protector for main power. Over-load protector, short circuit protector , over the upper limit temperature protector, over-temperature protector for controlling wiring

◆ Circulating Fan:Over-load protector, short circuit protector and anti-reversal protector

Ordering Information → Technical Parameters ↓ | BGD 886/S | BGD 887/S | BGD 888/S |

Working Room Size(W×H×D),mm | 900×400×600 | 1250×500×1000 | 1600×500×1000 |

Working Room Capacity (no including V shape cover) | 216 L | 600 L | 800 L |

Overall Size(W×H×D),mm | 2450×1550×1430 | 2830×1560×1830 | 3230×1656×1830 |

Power/Max. Current | 16KW/21A | 23.6KW/28A | 28KW/35A |

Power Supply | AC 380V 3 phase 20A | AC 380V 3 phase 23A | AC 380V 3 phase 25A |

Temperature Range | RT+10℃~80℃ | ||

Temperature Uniformity | ± 2℃ | ||

Temperature Stablity | ± 0.5℃ | ||

Humidity Range | 20%~98% | ||

Humidity Uniformity | ± 5% RH | ||

Humidity Stablity | ± 2% RH | ||

Salt Fog Precipitation | 1~2ml/ 80cm2.h(Adjustable) | ||

Spray Method | Continuous or Cyclical | ||

Required Work Environment | Tem.: 5~30℃;RH: 45%~85%RH;Barometric Pressure:86kPa~106kPa | ||

Required Air Supply | Air consumption: 1m3/h, Pressured air without water and oil which has been dried and filtered, pressure is (0.4~0.8)Mpa | ||

Required Water Supply | Supplied by tap water, which is used for humidifier to pressure, heat and filter air. Water pressure should be (0.2~0.4)Mpa Note:Distilled water or deionized water is required for preparing spray solution, water consumption is near 20L/24hour under continuous spraying) | ||

Note:Temperature uniformity and stability datas are tested under 25℃ environment temperature, RH ≤ 85%and no any samples

Biuged Precise Instruments (Guangzhou) Co.,Ltd

Add:NO.15, Fuzhong Rd., Zhongxin Town,

Zengcheng District, Guangzhou.China

Tel:+86-20-32955999;+86-20-32955820

Fax:+86-20-32955819

E-mail:jack@biuged.com

Website: http://www.biuged.com

Biuged Instruments Co.,Ltd.

Add:RM.310, NO.1, Sicheng Rd.,

Tianhe District, Guangzhou.China

Tel:+86-20-82169666

Fax:+86-20-32955818

E-mail:jack@biuged.com

Biuged Precise Instruments (Shanghai) Co.,Ltd

Add:No.1111, ZhongCai Industrial Park

1st floor,Zhu Feng Road, Qingpu District

Shanghai City, China.

Tel:+86-21-59240298

Fax:+86-21-59249719

E-mail:xjx@biuged.com

Biuged Laboratory Instruments (Guangzhou) Co., Ltd. Guangdong ICP record number:11044672

.png)