New Products in 2023 | Two Keywords: Automated & Intelligent

Release date:2022-10-31

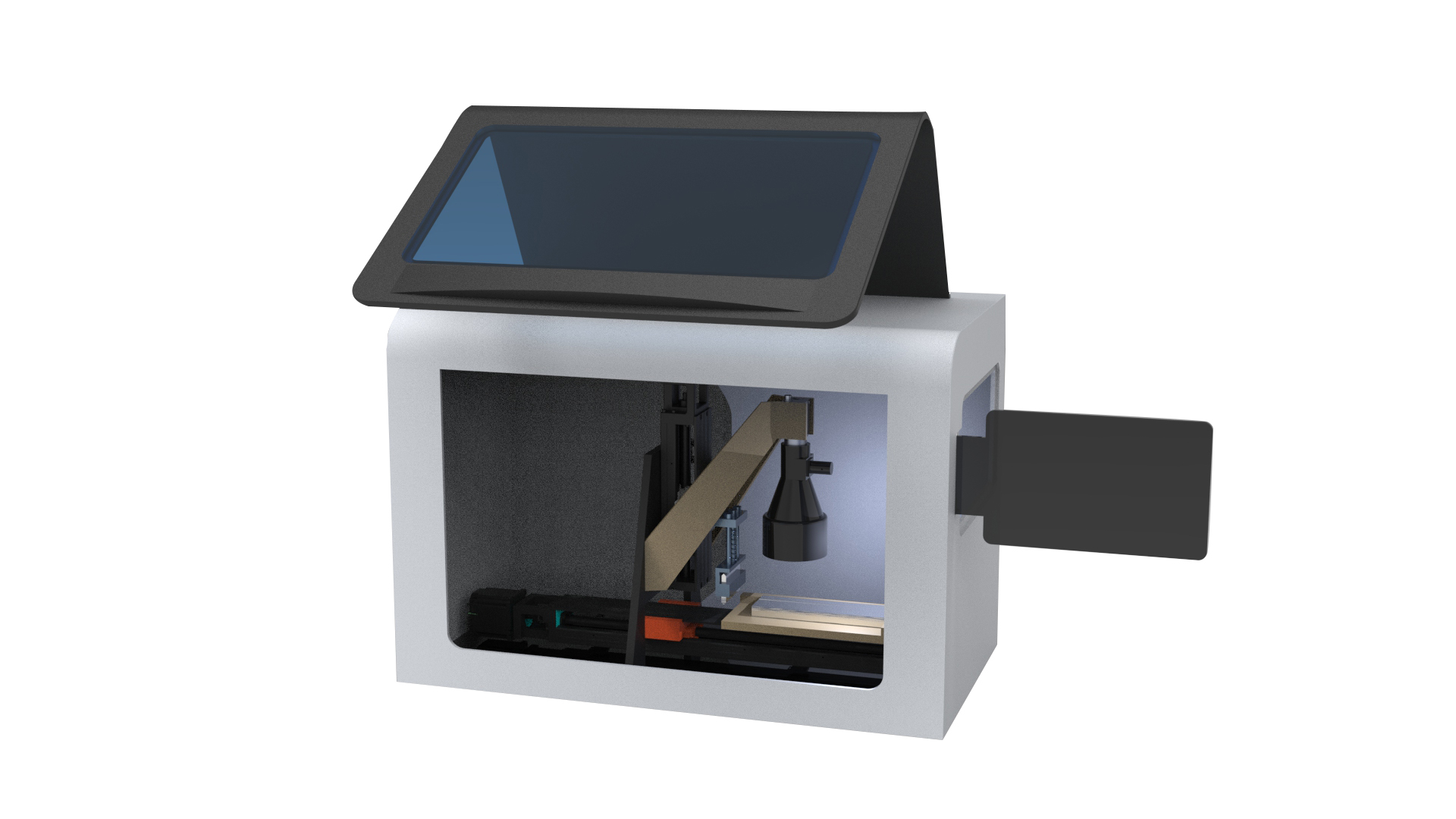

① Intelligent Fineness of Grind Gauges

Introduction: There are often large differences in the result judgment of scraper fineness, especially for low range fineness of grind gauges. One of the reasons is that the strength and speed of different operators are different when scraping the sample in the groove with a scraper. The second reason is that when reading, there are relatively large subjective factors in judging the number and distribution of particles, especially when it is required to read the test results quickly within 5 seconds.

BGD 246 Intelligent Fineness of Grind Gauges is an intelligent instrument newly developed by our company. This instrument can not only automatically complete the standard scraping of the sample on the groove of the instrument, but also immediately take and save the pictures of the sample particles in the groove. And according to the regulations of the result reading of the relevant standards, it can automatically identify the scraper fineness value of the sample within 5 seconds, and also display the statistical chart of particle distribution.

The instrument can adapt to different specifications, types and sizes of fineness of grind gauges, and it is equipped with MODBUS TCP/RTU communication port. The data storage capacity is large, which can effectively solve the problem of poor repeatability and reproducibility of the results when the scraper fineness is detected in the current industry, and greatly improve the work efficiency.

Main Technical Parameters

■ Range: 0~200μm (corresponding to a variety of scrapers, including 0~25μm, 0~50μm, etc., and the maximum is 0~200μm)

■ Speed: 50mm/s~150mm/s (adjustable)

■ Accuracy: ±5%

■ Minimum particle resolution: 5μm~10μm

■ Single measurement time: <2min

■ Ordering information:BGD 246---Intelligent Fineness of Grind Gauges

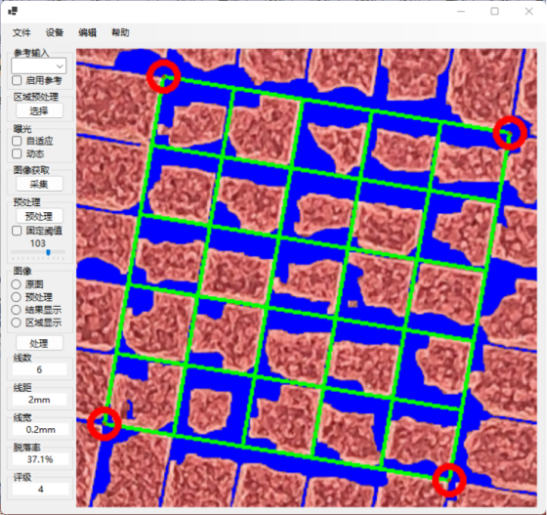

② Cross Hatch Test Image Recognizer

Introduction: After the cross hatch test of the film, the traditional method is for the operator to identify the peeling area with his own naked eye and carry out the corresponding rating. Since it is difficult to accurately quantify the peeling with the naked eye, there are relatively large subjective differences in the results or ratings, and it is easy to dispute. In order to solve this problem and improve the repeatability and reproducibility of the cross hatch test results, our company has developed an instrument that can automatically identify the peeling area.

The instrument uses computer digital image processing (visual automatic analysis) technology to take photos of the crossed test panel, and then analyze and calculate the digital images, which can quickly and easily obtain accurate results.

BGD 350 Cross Hatch Test Image Recognizer is composed of a hand-held cylindrical structure, which can be conveniently placed on the cross hatch area pattern to be evaluated. It is also equipped with a camera and an LED lamp with adjustable illumination intensity.

Features

◆ Different imaging modes are automatically selected by special hardware to optimize the contrast ratio of the surface to be evaluated.

◆ Automatic estimation of cutting quantity, cutting spacing and width of scratch channel, and manual adjustment to obtain accurate measurement.

◆ Automatically calculate the proportion of peeling and display the corresponding rating.

Main Technical Parameters

■ Maximum assessable range: 30mm×30mm

■ Maximum visual range: 35mm×35mm

■ Camera observation accuracy: 50px/mm

■ Light source: combined LED white light source

■ Language: English/Chinese

■ Operating temperature and humidity requirements: 5 ℃ ~ 40 ℃; relative humidity ≤ 80% (at 35 ℃), no condensation

■ Port: USB2.0,about 300mA

■ Minimum system requirements: i3 and above processor, USB2.0 port, Win7 operating system or higher, more than 600MB RAM

■ Overall size(mm): 120×68×68

■ Net weight: about 640g

■ Ordering information: BGD 350---Cross Hatch Test Image Recognizer

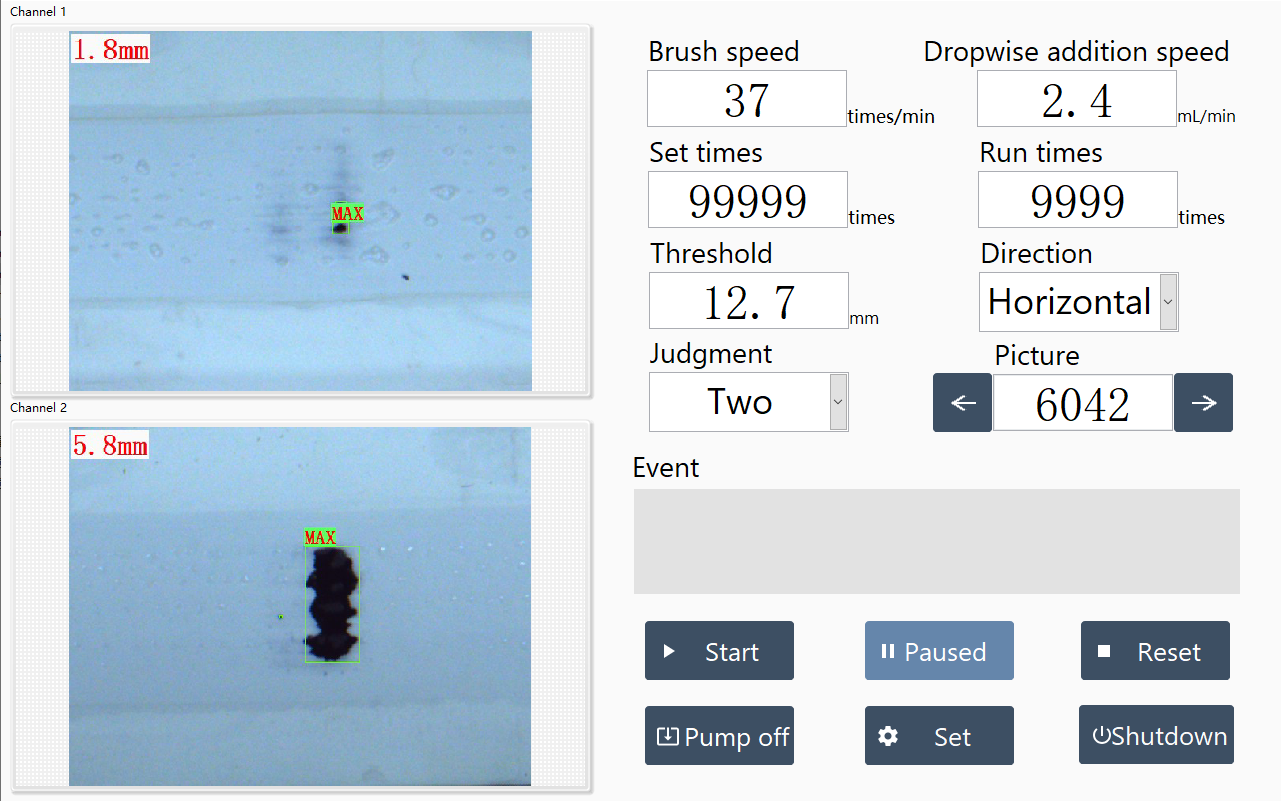

③ Multifunction Wet Abrasion Scrub Tester With Image Recognition

Introduction: For the wet abrasion scrub of architectural coatings and related products, it is generally defined that the end point of the test is that the coating is abraded to a certain length: the inner wall coating is exposed in the 100mm coating area in the middle of the test panel, and the outer wall coating and ASTM 2486 method are that the damaged length exceeds the shim width (12.7mm). To accurately determine the end point of the test, it is not only necessary for the operator to have a preliminary prediction of the wet abrasion scrub times of the test samples, but also for them to be able to accurately identify the length of the abraded coating. However, it is quite difficult in actual operation.

BGD 528/S Multifunction Wet Abrasion Scrub Tester is equipped with the function of automatically identifying and calculating the length of the test sample from being abraded to the substrate (exposed bottom). It can monitor the wet abrasion scrub of the samples of two channels at the same time, no need to look at the sample on site. Once the exposed length of the test sample reaches the "threshold" set by the operator, the instrument will automatically stop and record the current scrub times, so as to truly achieve unattended. In addition, the operator can also browse the actual pictures of the test panel after scrubbing for any number of times, and can export the pictures to the U disk for checking.

Features

◆ Double working channel, each channel can measure the length of the exposed bottom visually.

◆ Microsoft surface is used as the control computer, equipped with a 10.5-inch touch screen, which can display clearly and run smoothly.

◆ Adopt silent structure design, the running speed is stable and uniform, and the test results are reliable.

◆ The user can freely set the flow rate of the washing liquid and precisely control it through the peristaltic pump.

◆ It is very convenient to load and unload the test panel and replace the abrasion head of different standards.

◆ All machine is made of aluminum alloy, which is beautiful, firm and durable.

Main Technical Parameters

■ Speed: the setting range is (5~95) times/min, and the visual detection range is (5~60) times/min

■ Stroke length: 0~300mm (adjustable), can meet different test requirements

■ Range of count: 0~99,999 times

■ Capacity of liquid container: 550mL×2

■ Power: AC 110V/220V, 50Hz/60Hz

■ Overall size(W×D×H, mm): 550×570×800

■ Net weight: 60 KG

■ Ordering information: BGD 528/S---Multifunction Wet Abrasion Scrub Tester With Image Recognition

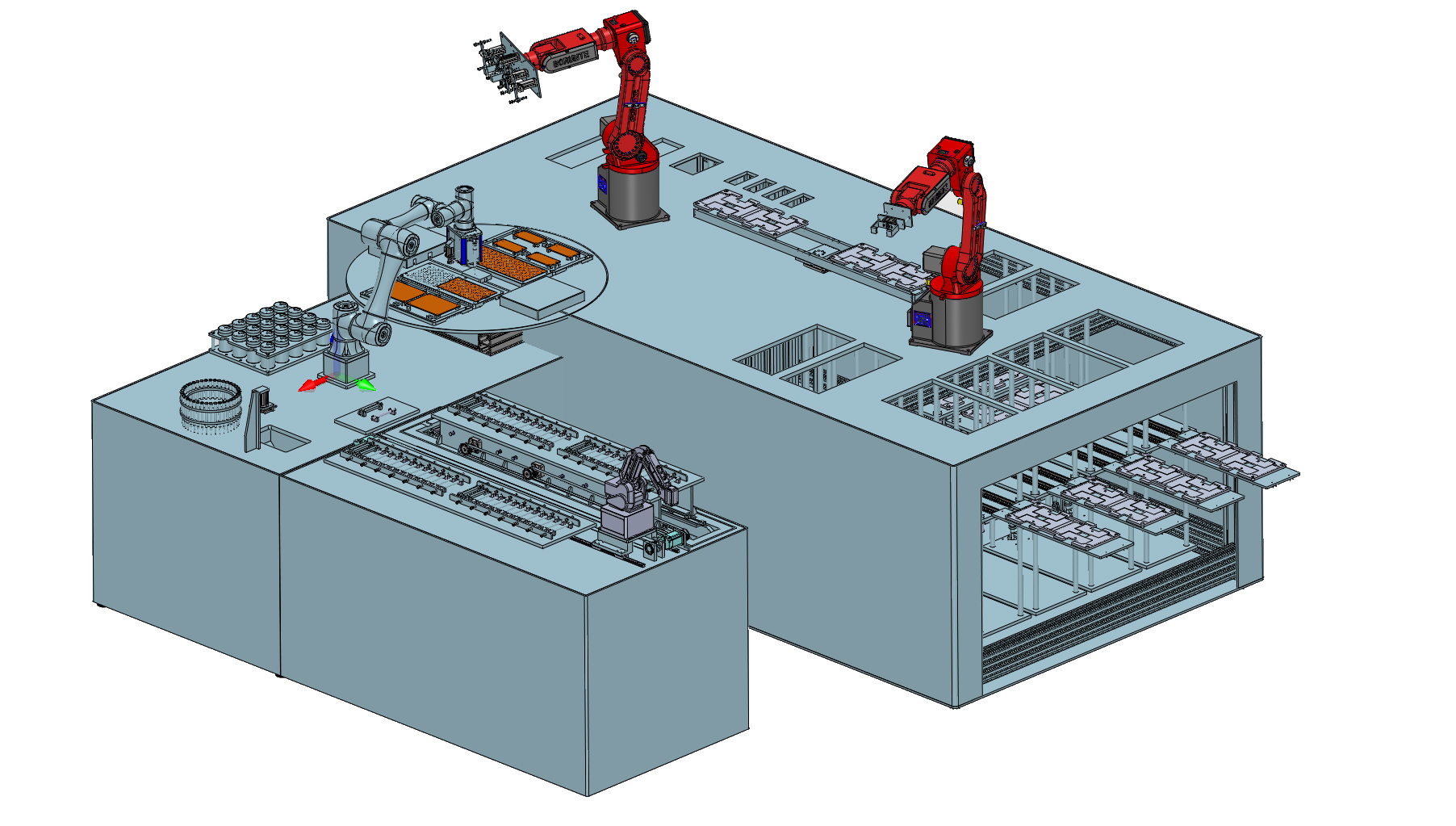

④ Automatic Preparation System for Test Specimens of Architectural Coatings

BGD 360 Automatic Preparation System for Test Specimens of Architectural Coatings is suitable for those test specimens applicated by rods. It has the following features:

◆ Fully automatic batch preparation of test specimens, almost without manual participation, to meet the needs of large-scale preparation of specimens with high consistency.

◆ Specimens digital management is adopted, which can encode and record coating specimens and prepared specimens, so as to realize the traceability management of specimens.

◆ According to the requirements of the different standards, operator can finish specimens preparation on Chart, PVC Film and Asbestos-free Cement Panel automatically.

◆ Use robot-arm to applicate coating films. This system includes a vacuum drawdown plate and a common plate for cement panels, which can achieve uniform coating film easily on different substrates.

◆ Blank test panels is automatically fed according to the demands, and automatically unloaded to the standard specimens tray after finishing coating , which is convenient for maintenance.

◆ Automatic cleaning device for applicating tools: after finishing one coating film, the applicating tools will be automatically cleaned, and then the next coating film will be carried out.

◆ The system adopts friendly human-computer interface, with intuitive display, convenient operation and real-time monitoring of running status.

Main Technical Parameters

■ Specification and Capacity of Test Specimens:250mm×140mm Charts(50pcs);

150mm×70mm Asbestos-free Cement Panels(500 pcs);

430mm×150mm Asbestos-free Cement Panels(100 pcs);

432mm×165mm Black Plastic Panels(100 pcs)

■ Specimens Preparation Rate:20 samples per 12 hours(about 400pcs test specimens)or

10 samples per 10 hours(about 200pcs test specimens)

■ Single Working Cycle:10~12 hours(10~20 samples)

■ Applicating Tools Capacity:4 sets of specimens preparation

■ Number of Specimens Trays:20 sets of specimenss

■ Cover Area:approximate 30m2

■ Total Power:5 kW

■ Ordering Information: BGD 360---Automatic Preparation System for Test Specimens of Architectural Coatings

⑤ Automatic Spray Sepeicmens Preparation Workstation

BGD 370 Automatic Spray Sepeicmens Preparation Workstation is a fully automatic spraying sepecimens preparation workstation integrating automatic panel taking, automatic spraying and automatic drying. This workstation adopts cooperative robot, with spraying and drying functions, and can automatically and quickly prepare standard size sepecimens for testing. It has the following features:

◆ Portable robot hand with high degree of automation, integrating automatic panel taking, automatic spraying and automatic drying.

◆ With treatment device for spraying waste gas:automatic water channel and water curtain, dry and wet treatment at the same time, try to avoid air pollution.

◆ Built in integrated drying device.

◆ Two clamping methods of test panel are optional:two 30mm diameter vacuum sucker are used during feeding, which can compensate the error of inconsistent height of test panel. Air claw clamping mode is adopted during unloading.

◆ Graco 24P993 spray gun is used for spraying: the nozzle diameter is 1.0mm, the spraying range can be adjusted by pressure, the atomization pressure is 0~0.7MPa, the spraying pressure is 0~0.7MPa, and the feeding pressure is 0-0.7MPa. The pressure can be automatically adjusted, and the control of the coating flow and the automatic control of the spraying pattern can be realized.

◆ Pressure feeding device is used for coating and solvent, and automatic color change valve switching device is installed. After spraying, it can be switched to solvent pipeline to clean, and finally switched to air pipeline to clean the residual solvent.

◆ The workstation is equipped with 2KW baking room, the maximum baking temperature can reach 150 ℃, and the test panel after spraying can automatically realize baking function.

◆ The workstation is equipped with active exhaust and filtration function, in which the water curtain adopts submerged pump for water circulation. 1.1KW three-phase AC motor with wind wheel is used for air exhaust.

Main Technical Parameters

■ Standard Size of Test Panels:150mm×70mm

■ Maximum Number of Spray Test Panels:10 pcs(depends on oven capacity)

■ Spray Speed:0-500mm/s(adjustable)

■ Dimension:1430mm×1430mm×1900mm(L×W×H)

■ Total Power:4 KW

■ Ordering information:BGD 370---Automatic Spray Sepeicmens Preparation Workstation

Biuged Precise Instruments (Guangzhou) Co.,Ltd

Add:NO.15, Fuzhong Rd., Zhongxin Town,

Zengcheng District, Guangzhou.China

Tel:+86-20-32955999;+86-20-32955820

Fax:+86-20-32955819

E-mail:jack@biuged.com

Website: http://www.biuged.com

Biuged Instruments Co.,Ltd.

Add:RM.310, NO.1, Sicheng Rd.,

Tianhe District, Guangzhou.China

Tel:+86-20-82169666

Fax:+86-20-32955818

E-mail:jack@biuged.com

Biuged Precise Instruments (Shanghai) Co.,Ltd

Add:Room 906, 9th Floor, Zhongcai Industrial Park, No.1111

Zhu Feng Road, Qingpu District, Shanghai, China

Tel:+86-21-59240298

Fax:+86-21-59249719

E-mail:xjx@biuged.com

Biuged Laboratory Instruments (Guangzhou) Co., Ltd. Guangdong ICP record number:11044672

.png)